Overview

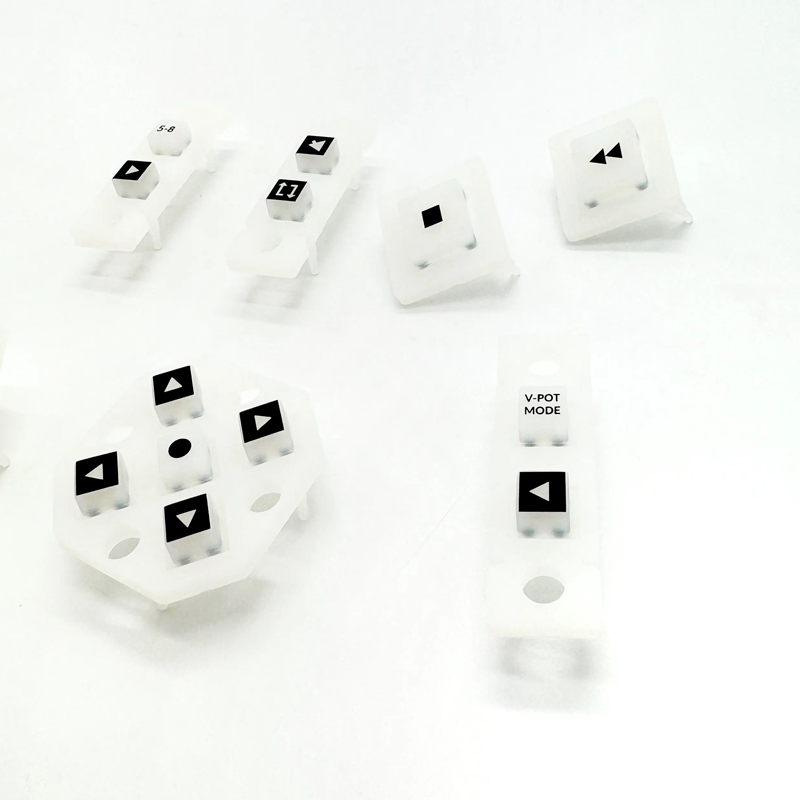

The Laser Mark Backlight Rubber Silicone Keypad is a customizable input solution made from translucent silicone rubber, designed for applications requiring backlighting. The surface is coated with colorful ink through spraying or screen printing, while the legends or backgrounds are created by laser cutting to allow LED backlight visibility. This innovative design enhances user experience with clear, illuminated key markings, making it ideal for a variety of devices that need both durability and aesthetic appeal.

Features

Place of Origin :Xiamen, China![]()

Brand Name: OEM

Material :PET, PC, PVC, Rubber, Silicone

Advantages: Water-proof, Durable, Eco-friendly

Printing :Laser Etching

Size: Customized Size

Process :Compression Molding

Color :Customized Color

Logo :Customized Logo

Advantages of Our Product

- Durability: Silicone rubber keypads are highly resilient, offering long-lasting performance even in harsh conditions. They withstand repeated use without degradation.

- Flexibility: The material’s inherent flexibility allows for the design of keypads that are comfortable to use and adaptable to various shapes and sizes.

- Temperature Resistance: Silicone rubber maintains its properties across a wide temperature range, from -40°C to 250°C, making it suitable for extreme environments.

- Chemical Resistance: Resistant to oils, solvents, and other chemicals, silicone rubber keypads are ideal for applications in industries where exposure to harsh substances is common.

- Tactile Feedback: Provides excellent tactile feedback with a soft and responsive touch, enhancing user experience and ease of operation.

- Waterproof and Washable: The keypads are inherently waterproof, which makes them easy to clean and ideal for applications requiring frequent sanitation.

![]()

One-Stop Service for Silicone Rubber Keypads

- Design Consultation: Expert guidance on design optimization and manufacturability to meet your specific requirements.

- Prototyping: Creation of functional prototypes to validate design and performance before mass production.

- Custom Molding: Precision silicone compression molding to produce high-quality, durable keypads with custom shapes, sizes, and colors.

- Printing and Finishing: Advanced techniques including silk screen printing, laser etching, and surface coatings for clear legends and enhanced durability.

- Quality Control: Rigorous inspection processes to ensure product consistency, performance, and compliance with industry standards.

- Assembly and Packaging: Comprehensive assembly services and custom packaging solutions to streamline logistics and reduce overhead costs.

- After-Sales Support: Ongoing support and service to address any issues and ensure continued satisfaction with your silicone rubber keypads.

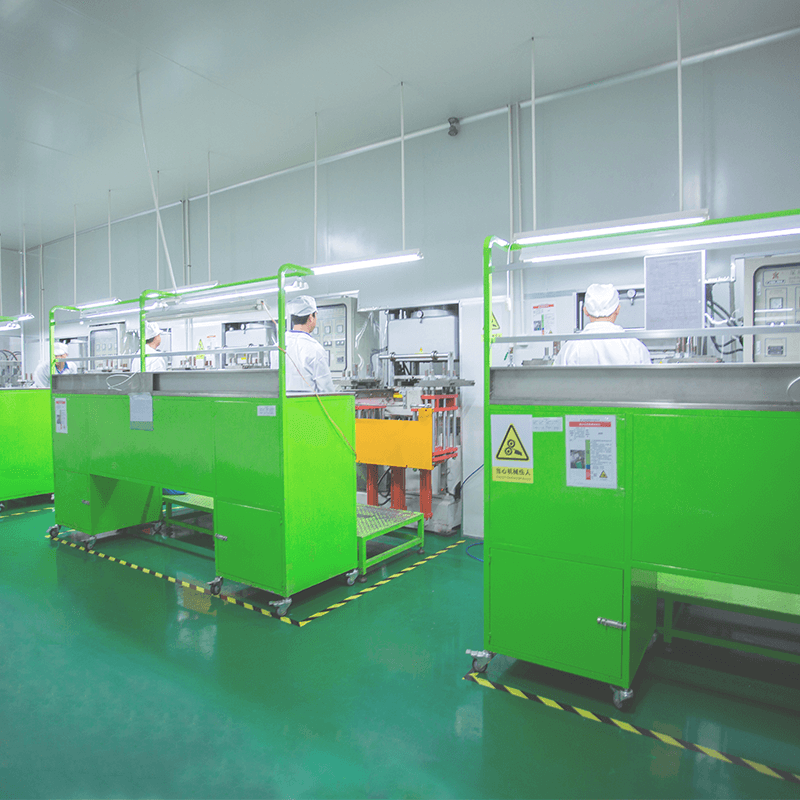

Factory Show

Our facility boasts a professional, fully automated production line complemented by a highly skilled quality control team. We utilize advanced machinery, including automated driver lines for high-volume efficiency, automatic screen printing machines for precise design application, and 3D measuring instruments for accurate dimensional checks. Additionally, our high-speed doming machines ensure durable, high-quality labels, while our die-cutting and CNC machines provide precise material cutting and machining. This combination of cutting-edge equipment and expert oversight allows us to deliver exceptional quality and efficiency in every project.