When designing electronic products, ensuring efficient communication between components is paramount, especially in products like silicone keypads and other devices requiring electrical conductivity. Conductive coatings offer a unique and practical solution, combining the benefits of non-conductive materials like silicone with the essential conductivity needed in many modern applications. In this blog, we’ll explore how conductive coatings work, their advantages, and why choosing the right conductive coating is critical for your product designs. At Flykeyboard, we specialize in providing cutting-edge solutions for silicone keypads, and our conductive coatings are engineered to meet the highest performance standards.

What Are Conductive Coatings?

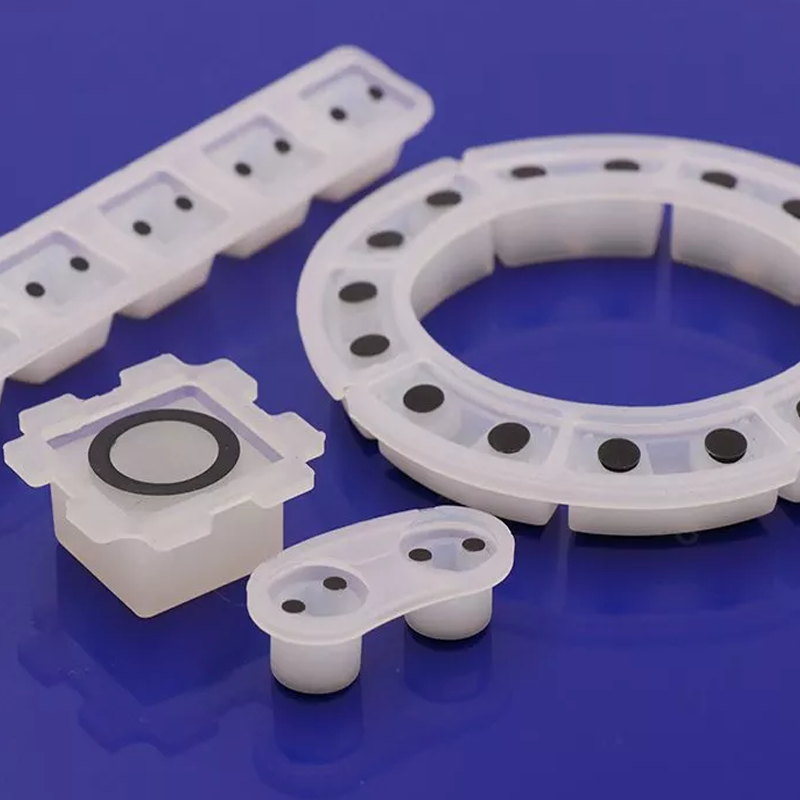

Conductive coatings are specialized coatings applied to non-conductive surfaces to enable electrical conductivity. In the context of silicone keypads, conductive coatings are vital because silicone, as a material, is inherently an insulator of electricity. When designing keypads, the ability to transmit electrical signals is crucial for ensuring that each key press activates the corresponding circuit. This is where conductive coatings come into play, facilitating the efficient transmission of electrical signals without compromising the integrity of the keypad’s design.

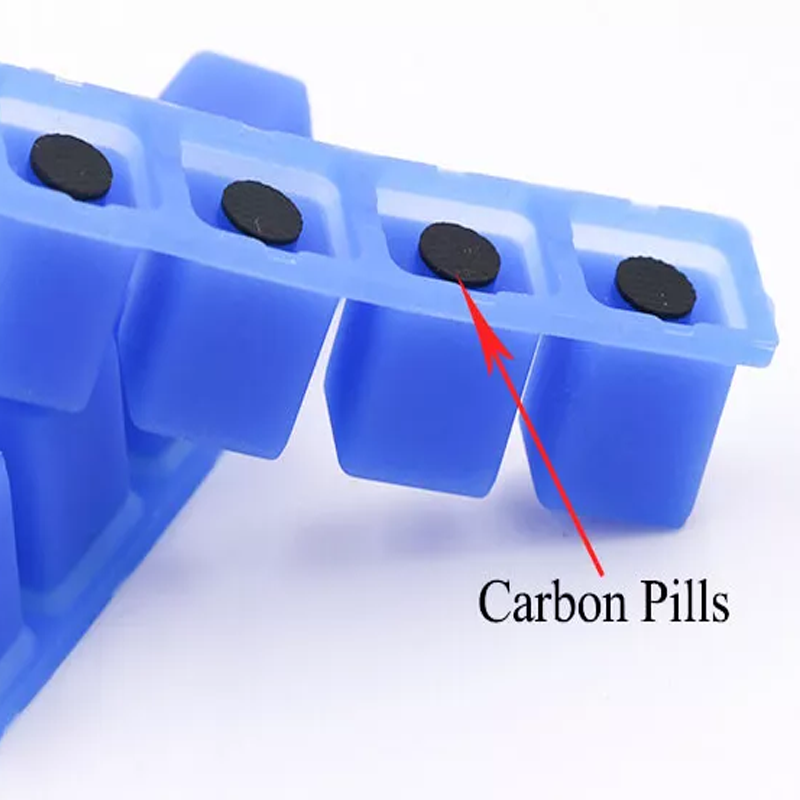

Conductive coatings are often made from a mixture of non-oxidizing metals, such as copper, which is typically around 25% of the solids in the coating. This allows the surface to conduct electricity while maintaining the flexibility, durability, and resilience that silicone offers. Conductive coatings not only ensure that the silicone keypads are functional but also help with static discharge, which is particularly important for sensitive electronics.

At Flykeyboard, we utilize a proprietary conductive silicone coating that is specially designed to work in tandem with our screened silicone inks and other components. This coating ensures that every silicone keypad we produce delivers optimal performance in its intended application.

How Do Conductive Coatings Work?

Technically, conductive coatings work by providing a conductive layer on a non-conductive substrate. When applied to silicone keypads, this coating ensures that when a key is pressed, the electrical signals pass through the rubber and complete the circuit, effectively registering the press. This is essential for user interface devices, especially in industries like medical equipment, telecommunications, and automotive, where accurate and responsive input is critical.

The conductive layer can either impede electrostatic charging or facilitate the rapid dissipation of accumulated charges. For example, in environments where static electricity can cause malfunctions or damage, the conductive coating helps prevent electrostatic buildup, ensuring that the keypads function reliably under various conditions.

Industries That Benefit from Conductive Coatings

Conductive coatings are indispensable in a wide range of industries, where the need for precise and efficient electrical conductivity is critical. Flykeyboard serves a variety of sectors, offering customizable conductive coatings for silicone keypads used in applications such as:

- Medical Devices: Ensuring that medical instruments, including diagnostic devices, function with precision and reliability.

- Telecommunications: Enabling responsive keypads for mobile phones, telecommunications equipment, and more.

- Electronics: Enhancing the performance of devices with keypads or switches.

- Automotive: Ensuring that keypads used in vehicles are durable and function in harsh environments.

- Point of Sale (POS): Supporting high-performance keypads used in retail environments.

- Industrial Equipment: Ensuring responsive input for machinery and control systems.

- Aerospace & Military: Providing reliable and resilient keypads for critical operations.

- Machinery: Supporting machinery with high-performance keypads that withstand demanding environments.

Key Benefits of Conductive Coatings

Conductive coatings offer numerous advantages, especially when applied to silicone keypads. Some of the primary benefits include:

- Adaptability to Various Designs: Conductive coatings can be tailored to fit a wide range of product designs, including keypads with complex shapes and sizes.

- Cost-Effective Solution: Applying conductive coatings is a cost-effective method for adding electrical conductivity to silicone keypads, particularly when compared to more expensive alternatives.

- Ease of Use: The application process for conductive coatings is straightforward and easy to manage, whether for large production runs or small-scale prototyping.

- Flexibility During Production: Conductive coatings can be applied to different surface areas, offering flexibility in how products are manufactured.

- Scalable for Large Volumes: Conductive coatings are easily scalable for high-volume production, allowing manufacturers to meet growing demand without significant capital investment.

- Low Contact Resistance: Conductive coatings ensure efficient electrical conductivity, minimizing energy loss and improving device performance.

- Durability and Longevity: Our wear-resistant conductive coatings form a homogeneous cross-linked bond with silicone products, ensuring long-lasting durability.

- EMI Shielding: The coatings also provide protection from electromagnetic interference (EMI), which is crucial in sensitive electronic applications.

- No Flaking or Chipping: Unlike some alternatives, our coatings do not flake or chip over time, ensuring long-term performance and reliability.

Application Process and Flexibility

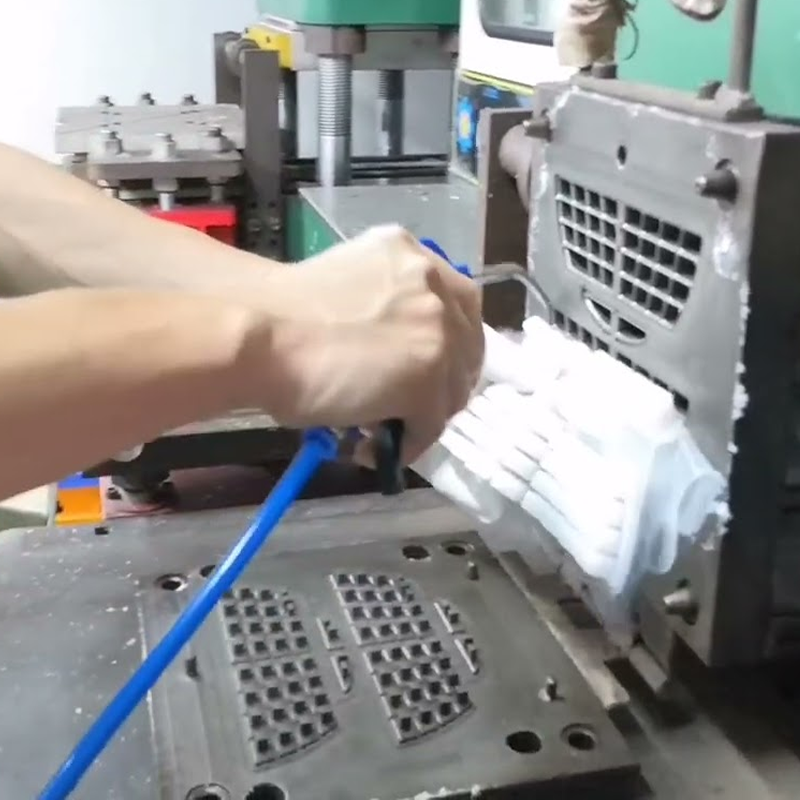

One of the key advantages of conductive coatings is their versatility in application. At Flykeyboard, we apply our coatings in a way that maximizes efficiency and precision. For large production runs, the coatings are sprayed onto the keypads using high-quality, low-pressure paint guns, ensuring an even application that adheres well to the silicone surface.

For small production runs or prototype batches, the conductive coating can be applied manually, allowing for more control over the thickness and coverage. In cases where only certain parts of the keypad need to be coated, we can mask off specific areas, ensuring that the coating is applied selectively without waste.

Additionally, if the desired thickness or uniformity is not achieved in a single application, the coating can be reapplied or built up in layers to meet specific requirements.

Why Choose Flykeyboard for Your Conductive Coating Needs?

At Flykeyboard, we are committed to providing the highest-quality conductive coatings for your silicone keypads and other electronic products. Our coatings are designed to deliver consistent performance across a range of industries and applications, ensuring that your keypads are both functional and durable. With our expertise in silicone products and conductive coatings, we can help you create the perfect solution for your needs.

If you’re looking to integrate conductive coatings into your product designs, Flykeyboard offers the expertise, experience, and customization options you need. Whether you’re developing a new product or optimizing an existing one, we can work with you to ensure that your keypads meet the highest standards of performance and reliability.

Get in Touch with Flykeyboard Today

At Flykeyboard, we understand the importance of high-quality materials and precision in product design. Our conductive coatings are an essential part of creating keypads that work seamlessly in various applications, from medical devices to industrial machinery. Contact us today to learn more about our conductive coating solutions and how they can help enhance the performance of your silicone keypads. Let us help you bring your product ideas to life with reliable, durable, and high-performance conductive coatings.

By partnering with Flykeyboard, you’re choosing a trusted provider of cutting-edge silicone keypads and conductive coatings that meet your industry’s needs. Reach out to us today to discuss your project requirements and discover how our solutions can help you achieve your design goals.