Selecting the ideal keyboard for your application can be a complex process. With the vast array of options available in the market, it’s essential to choose one that ensures functionality, durability, and user satisfaction. Whether you’re designing a keyboard for industrial machinery, medical devices, or consumer products, making an informed decision is crucial. At Flykeyboard, we specialize in creating high-quality, customized keyboards tailored to meet the specific requirements of various industries. This comprehensive guide explores the essential considerations for choosing the right keyboard while highlighting how Flykeyboard excels in delivering industry-leading solutions.

Key Considerations for Choosing the Right Keyboard

Assess the Operating Environment

Understanding the environmental conditions in which the keyboard will be used is a critical first step. Will the keyboard be exposed to moisture, dust, or extreme temperatures? Industrial environments, for example, often require ruggedized keyboards with robust materials and protective coatings to withstand harsh conditions. At Flykeyboard, we offer a range of solutions, including sealed keyboards and IP-rated designs, ensuring optimal performance in demanding environments.

Focus on User Interface and Usability

A well-designed user interface is essential for a seamless experience. The layout, button size, and tactile feedback all play a role in determining user satisfaction. Flykeyboard excels in creating ergonomically designed keyboards that prioritize ease of use and intuitive navigation, ensuring they meet the needs of both novice and experienced users. Whether you need a soft-touch interface or a more pronounced click, we provide custom tactile feedback options tailored to your specific application.

Prioritize Durability and Longevity

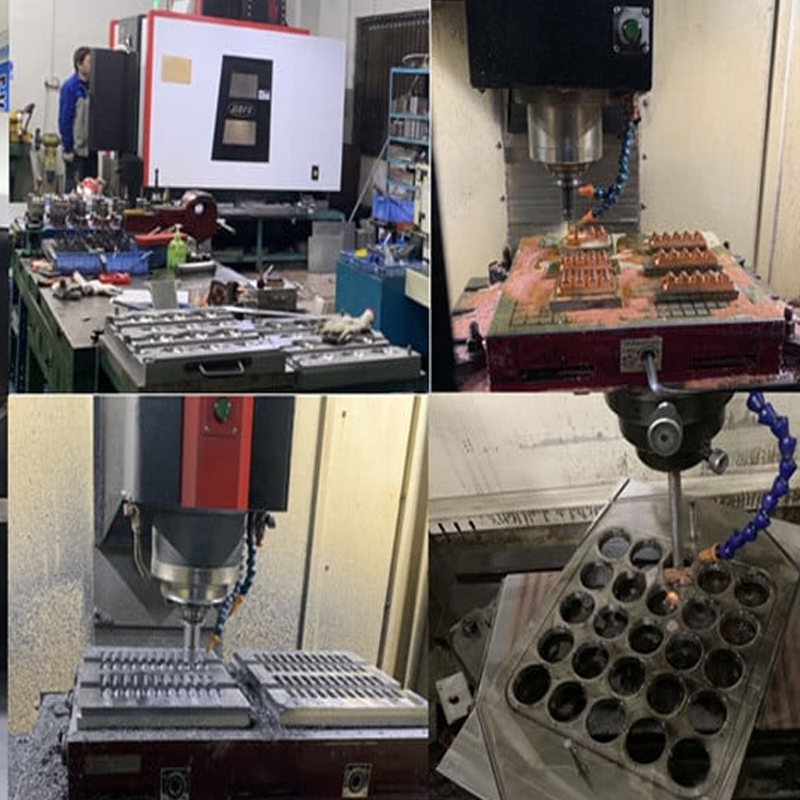

For keyboards subjected to frequent or intensive use, durability is paramount. Selecting high-quality materials such as polycarbonate overlays or UV-resistant coatings can significantly enhance the keyboard’s lifespan. Flykeyboard utilizes premium materials and advanced manufacturing techniques to ensure our keyboards maintain their integrity even in the most challenging conditions.

Ensure Compatibility with Your System

System compatibility is a non-negotiable aspect of keyboard selection. Factors such as electrical characteristics, connector types, and software integration must align with your existing setup. Flykeyboard’s expert engineering team conducts detailed assessments to guarantee seamless integration with your devices, preventing costly compatibility issues.

Explore Customization Options

Customization can elevate the functionality and aesthetics of your keyboard, making it a perfect match for your application. From unique layouts and custom branding elements to advanced features like backlighting and multi-language support, Flykeyboard offers extensive customization options. Our goal is to create keyboards that not only perform flawlessly but also enhance the overall appearance of your product.

Test Prototypes Before Production

Prototyping is an indispensable step in the development process. Testing a prototype allows you to evaluate the keyboard’s performance in real-world scenarios, identify potential issues, and make necessary adjustments before mass production. Flykeyboard provides rapid prototyping services, enabling you to test and refine designs efficiently, saving both time and resources.

Partner with a Trusted Supplier

The quality of your keyboard depends heavily on the expertise of your supplier. Flykeyboard is a trusted partner with years of experience in producing industry-specific keyboards. Our commitment to excellence, backed by ISO-certified quality control processes, ensures that you receive products that meet the highest standards.

Common Mistakes to Avoid

Overlooking Tactile Feedback

Tactile feedback is a vital aspect of user experience. A poorly designed keyboard that lacks clear feedback can result in errors and user dissatisfaction. At Flykeyboard, we understand the importance of tactile response and offer a variety of feedback options to suit diverse applications, from medical devices to industrial controls.

Ignoring Aesthetic and Branding Potential

While functionality is key, aesthetics should not be ignored. A visually appealing keyboard can enhance the perceived value of your product. Flykeyboard specializes in integrating branding elements such as custom logos, colors, and finishes, ensuring that your keyboard aligns with your product’s design language.

Neglecting Compliance Requirements

Industry-specific compliance standards are crucial, particularly for medical and industrial applications. For example, medical keyboards must adhere to stringent hygiene and safety regulations. Flykeyboard designs keyboards that comply with relevant industry standards, providing peace of mind and avoiding costly compliance issues.

![]()

Choosing Based Solely on Cost

While cost is a consideration, prioritizing the cheapest option can lead to long-term challenges, such as reduced durability or limited functionality. Flykeyboard focuses on delivering value-driven solutions that balance cost-effectiveness with superior quality, ensuring a wise investment for your product.

Underestimating Ergonomics

Keyboard ergonomics directly impact user comfort and productivity. Poorly designed keyboards can lead to user fatigue or long-term injuries. Flykeyboard integrates ergonomic principles into every design, offering optimized key placement, actuation force, and overall usability to enhance the user experience.

Overlooking Maintenance Needs

Maintenance requirements vary based on the keyboard’s materials and design. High-traffic keyboards may need frequent cleaning or additional wear-resistant features. Flykeyboard’s designs emphasize durability and low-maintenance solutions, minimizing downtime and ensuring consistent performance.

Failing to Account for Future Needs

As technology evolves, your keyboard’s design should accommodate potential upgrades or modifications. Flykeyboard offers scalable solutions that can be updated to meet changing requirements, ensuring long-term usability and adaptability.

![]()

Why Choose Flykeyboard?

At Flykeyboard, we are more than just a keyboard manufacturer; we are your partner in creating tailored input solutions that exceed expectations. Here’s why customers choose us:

– Industry Expertise: With extensive experience across industries, we understand the unique requirements of applications ranging from medical devices to industrial systems.

– Customization Excellence: Our keyboards are designed to meet your specific needs, offering advanced features and aesthetic options that align with your vision.

– Uncompromising Quality: Utilizing top-tier materials and precision engineering, we deliver keyboards that stand the test of time.

– Collaborative Approach: We work closely with you throughout the design and production process, ensuring that every detail is addressed.

– Reliable Support: Our team provides ongoing support and guidance, from initial concept development to after-sales service.

Conclusion

Choosing the right keyboard is a critical decision that impacts the functionality, durability, and user satisfaction of your product. By understanding the key factors involved and partnering with a trusted supplier like Flykeyboard, you can ensure a successful outcome. From ruggedized industrial keyboards to sleek, customized designs for consumer electronics, Flykeyboard is your go-to expert for innovative and reliable keyboard solutions.

Let Flykeyboard help you bring your vision to life. Contact us today to learn more about how we can meet your keyboard needs with precision and excellence.