When it comes to customizing silicone rubber keypads, one of the critical decisions is selecting the appropriate printing method for your design. Whether you’re creating sleek graphical overlays, intricate circuit layouts, or even 3D effects, understanding the differences between screen printing, digital printing, and pad printing is key to ensuring you achieve the highest quality result. At Flykeyboard, we specialize in providing expert insights and premium services to help you select the right printing technique for your silicone keypad production needs.

Let’s dive into the nuances of these three printing methods so you can make an informed decision for your project.

Screen Printing

Screen printing has long been the go-to method for printing circuits and graphic overlays on silicone rubber keypads. This process uses a woven mesh stencil to transfer ink onto the material or substrate. The stencil itself contains the actual artwork or design, and the screen is placed directly on top of the product. A squeegee is then used to push ink through the mesh, filling the open apertures and transferring the design onto the surface below.

While the process was originally referred to as silkscreen printing due to the use of silk fabric for the stencil, modern screen printing uses synthetic materials such as polyester, nylon, or stainless steel. These materials offer improved durability and precision. The advantage of screen printing lies in its ability to produce vibrant, opaque colors and high-definition lines, making it ideal for simpler designs with bold, defined shapes.

At Flykeyboard, we utilize state-of-the-art screen printing technology to ensure that your silicone rubber keypads have the crisp, clear design details they require. Whether you need high-quality circuit prints or complex graphic overlays, our screen printing process ensures accuracy and consistency across large production runs.

Digital Printing

Digital printing has revolutionized the world of graphics, especially when it comes to complex designs on silicone keypads. Unlike screen printing, digital printing doesn’t require a physical stencil or mesh. Instead, digital files created through graphic software are sent directly to a printer, where the design is printed onto the substrate using specialized ink.

One of the biggest advantages of digital printing is its ability to handle intricate, multi-colored, and complex designs. This method is ideal for membrane switches that incorporate 3D graphics, textures, fading, half-tones, and other visual effects that are difficult, if not impossible, to achieve with traditional screen printing. Digital printing allows for more precise color matching and the flexibility to print variable data without the need for extensive setup changes.

At Flykeyboard, we leverage the power of digital printing to bring your most sophisticated designs to life. Whether you need detailed logos, gradient effects, or photographic-quality imagery, our digital printing process offers unparalleled flexibility and precision.

Pad Printing

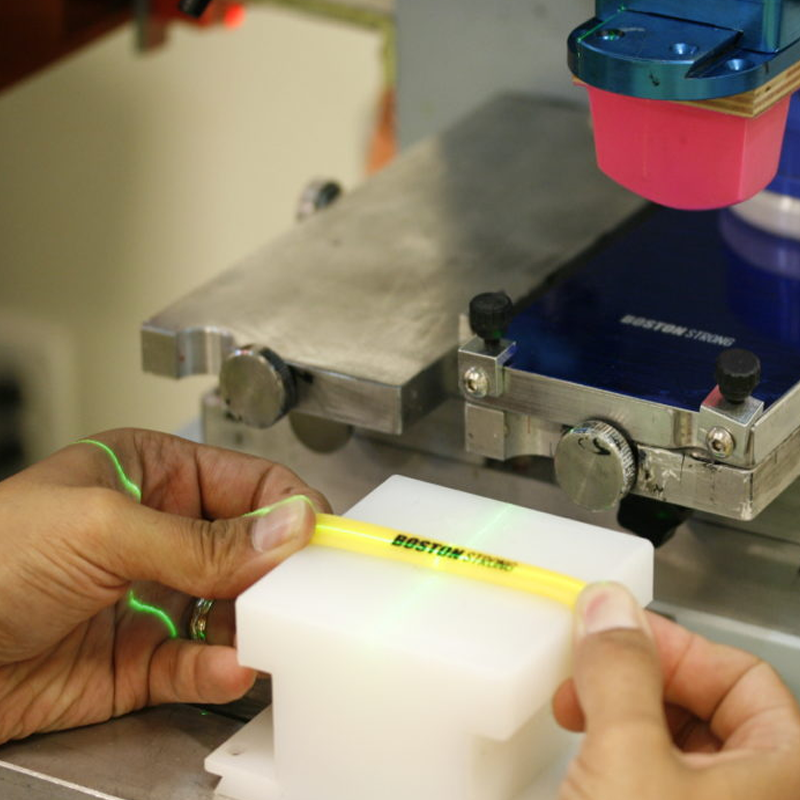

Pad printing, also known as tampography, is a unique method that enables the printing of 2D images onto 3D or irregularly shaped objects. This is a critical technique when working with products that have non-flat surfaces, such as silicone rubber keypads with complex curves or raised edges.

The pad printing process involves three primary components: an etched plate, a silicone pad, and the substrate. The image is first etched into a flat printing plate, which is then filled with ink. The silicone pad, which is smooth and chemically resistant, picks up the ink from the plate and transfers it onto the substrate. The flexibility of the silicone pad makes it an ideal material for adapting to irregular surfaces without absorbing the ink, ensuring a high-quality transfer.

Pad printing is commonly used in applications that require printing on hard-to-reach areas or 3D surfaces, such as control buttons, logos on curved surfaces, or small-scale objects that would be challenging to print using other methods. Its adaptability makes it an indispensable technique in the production of silicone keypads that require printing on non-flat or intricate surfaces.

At Flykeyboard, our pad printing expertise allows us to produce intricate designs on both flat and 3D surfaces with precision. Whether you’re working with curved keypads or non-standard shapes, our pad printing solutions ensure that every detail is transferred flawlessly.

Which Printing Method Should You Choose?

When choosing between screen printing, digital printing, and pad printing for your silicone rubber keypads, the decision ultimately depends on your design complexity, the surface you’re printing on, and the production volume.

- Screen printingis best suited for simpler, high-volume designs where color accuracy and line definition are paramount.

- Digital printingexcels with complex, multi-colored designs and effects, making it ideal for smaller runs or projects requiring flexibility and detail.

- Pad printingis perfect for printing on 3D objects or substrates with irregular surfaces, ensuring accuracy even on hard-to-reach areas.

At Flykeyboard, we understand that every project has unique requirements. That’s why we offer a range of printing services to meet the needs of our customers. Our team works closely with you to determine the best printing technique that aligns with your design goals, production timelines, and budget.

Conclusion

Choosing the right printing technique for your silicone rubber keypads is essential to achieving a high-quality, durable product. Whether you’re looking for the bold simplicity of screen printing, the detailed versatility of digital printing, or the precision of pad printing for irregular surfaces, Flykeyboard is here to help. We provide cutting-edge printing technologies and expert craftsmanship to ensure that your silicone keypads meet the highest standards of quality.

Ready to get started on your next silicone printing project? Contact us today to discuss your needs and learn how our printing capabilities can help bring your designs to life. Let Flykeyboard be your trusted partner in producing custom silicone rubber keypads with the finest printing methods available.