At Flykeyboard, we understand that your molds are not just tools—they’re vital assets in producing every keyboard you order. Ensuring the longevity and performance of these molds is one of our top priorities. With every injection cycle applying immense pressure—around 35 tons—directly to the mold, regular upkeep is essential to prevent wear and tear. Our commitment to meticulous maintenance safeguards the quality of your products and maximizes the lifespan of your molds.Let’s dive into the three pillars of mold care: cleaning, repair, and storage, which ensure optimal mold performance for years to come.

Comprehensive Cleaning Practices

Over time, mold surfaces naturally accumulate dirt, grime, and residue from repeated use. Left unchecked, these buildups can compromise the precision of your keyboard molds, affecting the final product’s quality. To counter this, our cleaning process is designed to be both thorough and precise.

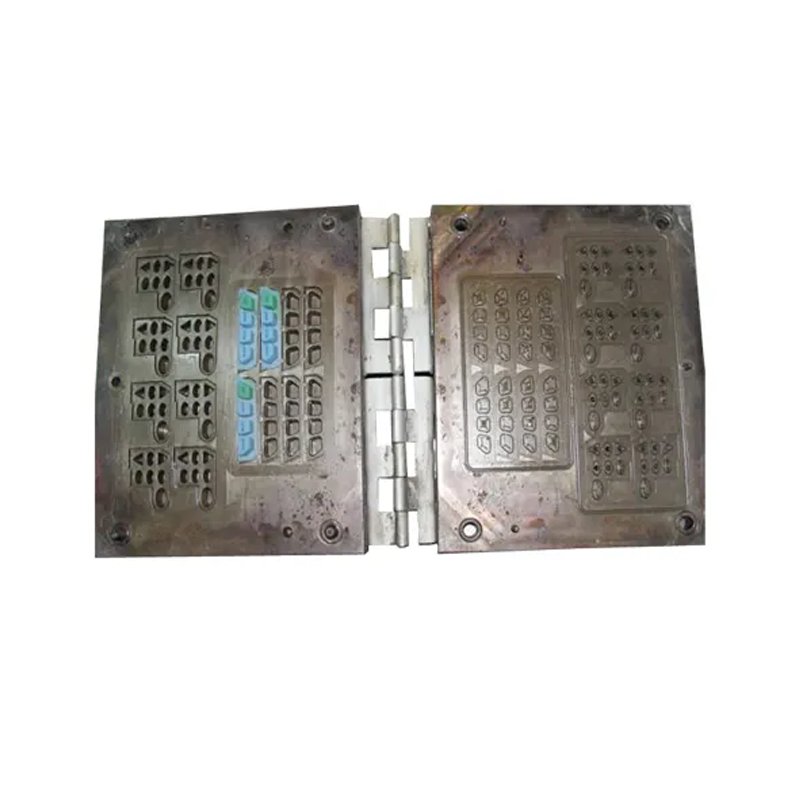

Every mold design has its unique characteristics, which means a one-size-fits-all approach simply doesn’t work. Some molds are intricately detailed and require specialized tools to clean fine crevices. Others may have delicate surfaces that demand gentle handling. Our skilled technicians approach each mold with patience, steady hands, and the right tools for the job.

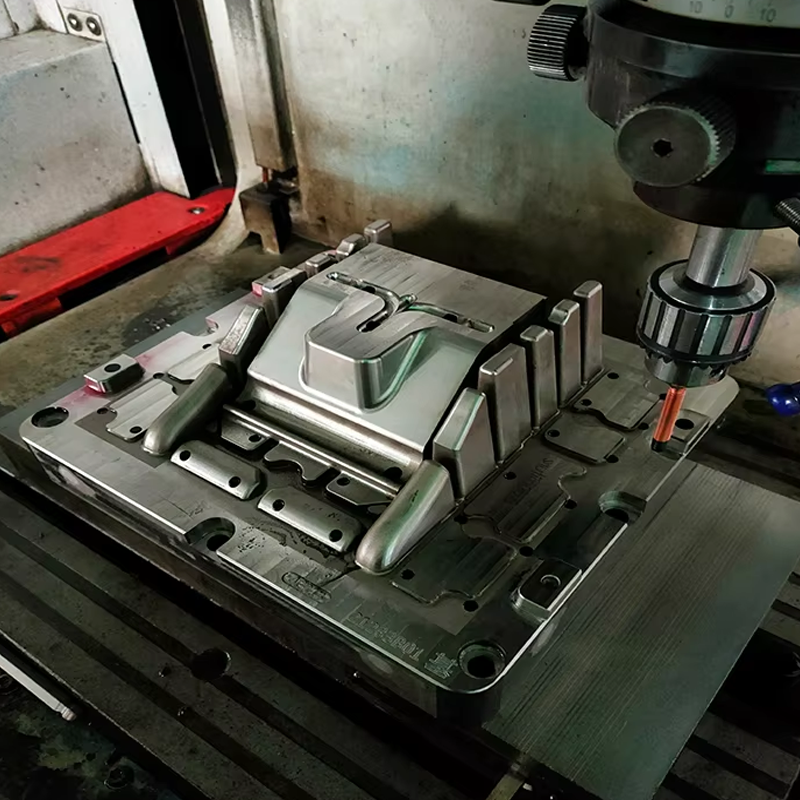

For more complex molds, disassembly is sometimes necessary to access tight gaps and hidden areas. Whether it’s removing residue from intricate grooves or polishing a high-gloss finish, our team ensures that every part of the mold is returned to pristine condition. This level of care not only enhances the immediate functionality of the mold but also prolongs its overall lifespan, ensuring you receive consistent, high-quality results.

Precision Repair and Maintenance

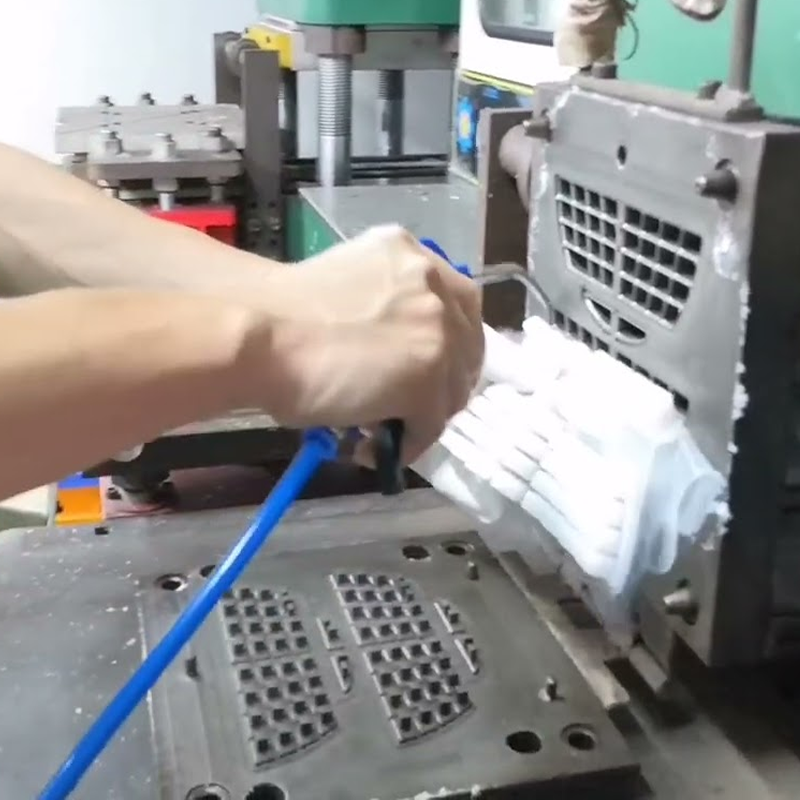

Despite our rigorous care standards, molds inevitably experience wear over time. With every injection cycle, minor imperfections like dents or scratches can emerge. These issues, while small, have the potential to impact the quality and consistency of your keyboard components.

Flykeyboard takes a proactive approach to mold repair. After each use, molds are thoroughly inspected for any signs of damage. When issues are identified, they are addressed by our in-house team of experienced engineers. These professionals are equipped to handle delicate repairs, ensuring the mold’s structural integrity and functionality are restored.

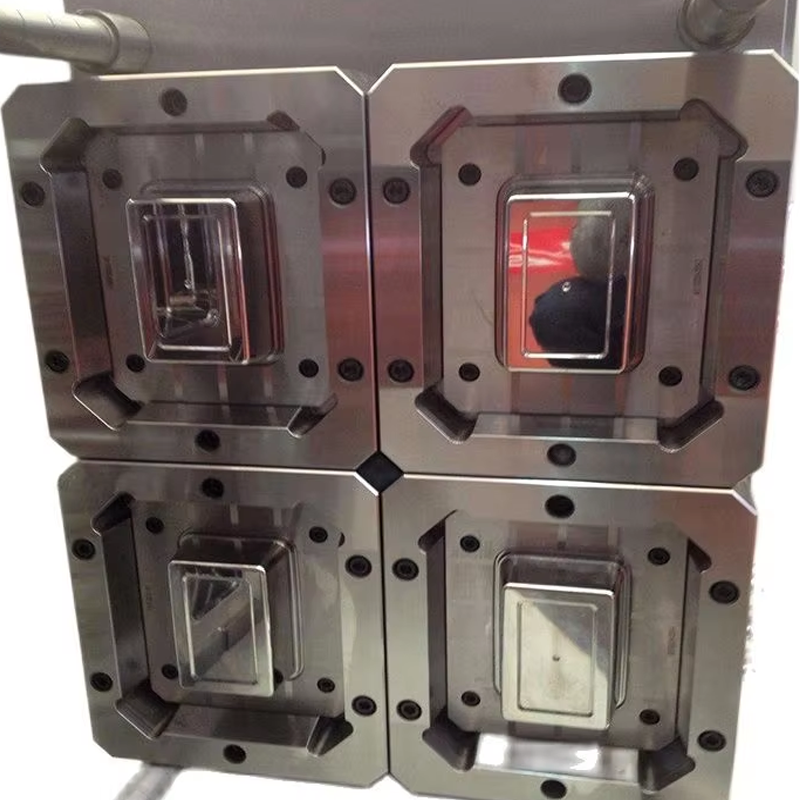

Some molds, such as those with polished or mirrored surfaces, require more frequent maintenance. Polished molds are particularly susceptible to scratches, which can mar the surface of your final product. To prevent this, these molds are periodically polished to maintain their smooth finish. We also create individualized maintenance schedules for molds that are prone to recurring damage based on their design. This personalized approach ensures that even the most high-maintenance molds continue to perform at their best.

Protective measures are integral to our repair and maintenance process. Molds are always handled with care, whether it’s covering them with protective mats when not in use or cleaning them using non-abrasive materials like cotton and wooden tools. By prioritizing these small yet significant actions, we protect your investment and maintain the high standards you expect.

Secure Storage Solutions

Proper storage is just as critical as active maintenance when it comes to preserving your molds. Once your order is complete, our team inspects and tags each mold, documenting its condition and any required maintenance. Before being stored, molds undergo necessary cleaning or repair to ensure they are in optimal shape.

Molds are stored in a closed position to shield their surfaces from dust, dirt, and accidental damage. This controlled environment keeps them safe and ready for future use. When a new order is placed, the mold is retrieved from storage, given a quick inspection to confirm its readiness, and carefully prepared for the next production cycle.

This seamless storage-to-production process minimizes downtime and ensures consistent quality for every keyboard mold we produce. Our storage solutions are not just about preserving molds—they are about maintaining the trust our customers place in us to care for their tools as if they were our own.

Why Flykeyboard?

At Flykeyboard, we don’t just manufacture keyboard components; we create solutions that support the longevity and quality of your molds. Our dedicated team of engineers works tirelessly to implement the best practices in cleaning, repair, and storage, ensuring that your molds remain in peak condition for as long as possible.

We believe in building partnerships with our customers by offering services that go beyond standard expectations. Whether it’s the personalized maintenance plans we design for your molds or the secure storage solutions we provide, everything we do is driven by our commitment to excellence.

If you’re ready to experience the Flykeyboard difference and learn more about how we can enhance the life and performance of your keyboard molds, don’t hesitate to contact us today. Together, we can ensure the quality and consistency of your products for years to come.