Overview

The Aircraft Keypad, also known as the aviation or aircraft keyboard, is a specialized input device made from durable silicone rubber, designed for use in flight simulators, aerospace, and military applications. Manufactured to withstand harsh working environments, these keypads are engineered to resist extreme temperatures, UV light, and abrasion. In addition to their ruggedness, aircraft keypads feature high conductivity, typically achieved through the integration of metal domes or metal pills, ensuring responsive and sensitive performance. The robust design and reliable conduction make them ideal for demanding aviation and defense sectors, providing both durability and precision in critical applications.

Details

– Origin:Xiamen, China

-Brand:OEM

– Keypad Material:Silicone

– Key Features:Durability, Chemical Resistance, Weather Resistance, Temperature Tolerance

– Applications:Home Appliances, Industrial Equipment

– Custom Orders:Accepted

– Color Options:Multicolor Printing

– Materials:Silicone, PVC, PET, PC, Metal, Adhesive-Backed Materials

– Environmental Considerations:Eco-friendly inks and materials

– Size:Customizable

– Logo:Custom Branding Available

– Accepted Artwork Formats:AI, PDF, CDR

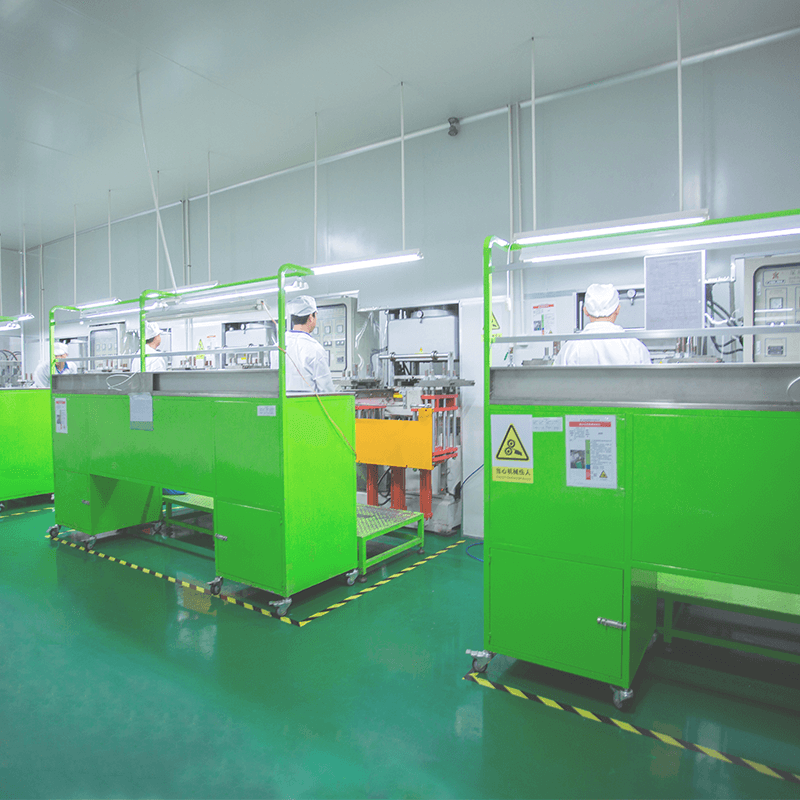

Quality Control

To ensure the highest quality of our silicone keypads, we implement a multi-channel inspection process

and support third-party inspections.

We also accept returns of any unqualified goods without reason. Below are the key steps in our quality assurance process:

Silicone Keypad Alcohol Abrasion Test

This test involves continuously rubbing the surface of the silicone buttons to ensure that the text and coating remain intact

and do not wear away or abrade over time.

Silicone Keyboard Material Tensile Force Test

We test the tear strength and tensile force of the silicone material to ensure the keypads are durable and resistant to tearing.

Why Choose Us

-

Multi-Language Capability:

– Our team is proficient in multiple languages, ensuring seamless communication with clients from diverse linguistic backgrounds. This capability allows us to effectively understand and meet your specific needs, regardless of your location.

-

On-Site Material Inspection:

– We conduct thorough on-site inspections of all materials before they are used in production. This rigorous process ensures that only the highest quality materials are utilized, maintaining the integrity and durability of the final product.

-

Design-Based Customization:

– We offer extensive customization based on your design requirements. Our experienced engineers collaborate closely with you to develop molds that precisely match your specifications, ensuring optimal performance and functionality.

-

Finished Product Inspection:

– Each finished product undergoes a comprehensive inspection to verify it meets all quality standards and customer specifications. This meticulous approach guarantees that you receive products of the highest quality and reliability.

-

Sample-Based Customization:

– We provide customization based on sample submissions. This process allows us to replicate and enhance existing designs, ensuring the final product aligns perfectly with your expectations.

-

Full Customization:

– We offer full customization services, tailoring every aspect of the mold to your specific needs. From design to production, we ensure that every detail is customized to meet your unique requirements.

-

OEM Services Available:

– Our OEM services allow us to create entirely new designs based on your concepts. We handle everything from initial design to final production, delivering innovative solutions that set your products apart.

Quality Documentation

- ISO 9001:2015 Certification

- IATF 16949 Certification

- First Article Inspection (FAl)

- PPAP Report(Production Part Approval Process)

- Material Technical Data Sheets (TDS)

- CMM Inspection Report

- SPC Report (Statistica Process Control)

- Material Certificates

- Dimensional Inspection Report (CMM)

- DFM feedback