Overview:

Our Custom ABS & PC Injection-Molded Keypad Enclosures deliver premium, precision-engineered housings tailored for smart garage door video and control systems. Crafted from high-impact ABS or polycarbonate via state-of-the-art injection molding, each enclosure is subsequently CNC-machined and surface-finished to exacting tolerances, ensuring seamless integration with touch interfaces and camera modules. As a full-service OEM partner, we provide end-to-end customization—including tailored geometry, Pantone color matching, logo application, and bespoke packaging—ensuring your product combines sleek aesthetics with industry-leading durability.

Specifications:

| Attribute | Details |

|---|---|

| Origin | Xiamen, China |

| Brand | OEM |

| Intended Use | Smart Garage Door Video & Control Panels |

| Housing Material | ABS or Polycarbonate (PC) |

| Surface Options | Matte, Gloss, or Custom Texture |

| Color Matching | Any Pantone®-Matched Shade |

| Decoration Methods | Pad Printing, UV Laser Etching |

| Sample Lead Time | 5–7 Days |

| Certifications | ISO 9001, RoHS, UL 94 V‑0 |

| Manufacturing Process | Precision Plastic Injection Molding |

| Dimensional Tolerance | ±0.10 mm (as molded) / ±0.05 mm (after machining) |

| OEM Services | Custom Geometry, Wall Thickness, Branding & Packaging |

| MOQ | Flexible—Prototypes to Mass Production |

| Lead Time | 20–30 Days (depending on complexity) |

| Packaging | Custom Retail-Ready or Bulk |

Production Advantages:

- Advanced Injection Molding Control

Precise cavity temperature and pressure regulation ensure uniform wall thickness and dimensional fidelity, critical for tight sealing around video sensors. - Integrated CNC Finishing

Secondary CNC operations refine mounting slots and alignment features to ±0.05 mm, guaranteeing a secure, tool‑free assembly. - High‑Performance Surface Treatments

In‑mold texturing or post‑mold painting delivers robust scratch resistance and premium hand‑feel, enhancing product longevity. - Optimized OEM Workflow

From CAD-driven mold flow analysis to automated in‑line inspections, our seamless production pipeline minimizes lead times and upholds rigorous quality standards.

Quality Assurance:

Under our ISO 9001 framework, every enclosure undergoes a comprehensive inspection regimen. We execute injection parameter audits, CMM‑based dimensional verifications, and optical surface scans to detect micro‑defects. Enclosures are subjected to UL 94 V‑0 flammability testing, accelerated UV and thermal cycling, and impact resilience trials. Final products receive 100% in‑house review before packaging to ensure steadfast performance in harsh outdoor environments.

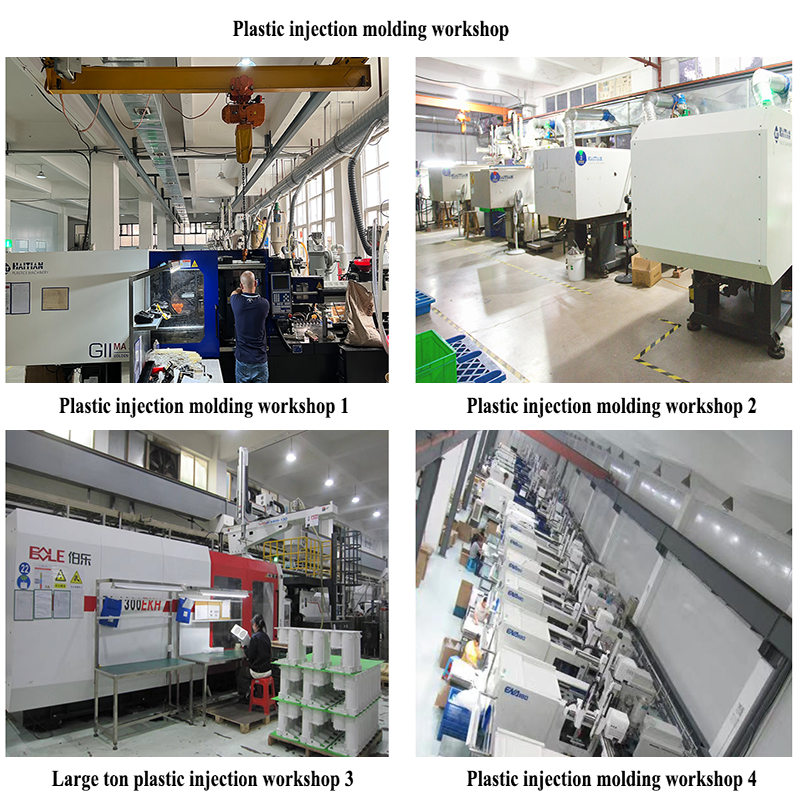

Factory Capabilities:

Our cutting‑edge facility boasts 5‑axis CNC and mirror EDM tooling suites, complemented by slow‑speed wire EDM for intricate features. We deploy 30 injection molding presses (50–350 tons) with advanced hot‑runner systems for rapid cycles and minimal waste. QA instruments—including 3D optical projectors, durometers, tensile testers, and coordinate measuring machines—uphold exacting tolerances. Accredited to ISO 9001 and compliant with RoHS and UL 94 V‑0, our automated drying ovens, robotic assembly stations, and precision die‑cutters enable scalable, high‑quality production for sophisticated smart garage door video solutions.